CCV Condensate Units

RECEIVER: Cast iron receivers are standard. Steel receivers are available as an option. Maximum internal receiver pressure is 5 psi. Receivers are designed for venting to atmosphere.

PUMP: Bronze fitted centrifugal design, flanged to the receiver with leakless mechanical shaft seal. The seal chamber has a relief line back into the receiver to prevent air pockets or collection of abrasives near the mechanical seal. Motor and rotating assembly are removable without disturbing retum or discharge piping. Maximum water temperature at pump suction is 210°F.

MOTOR: Drip-proof ball bearing design. Units are available with 1750 RPM or 3450 RPM motors.

FLOAT SWITCH: One for each pump, provides automatic operation, mounted and wired on unit.

STARTERS: All polyphase units (208-230/460v), and integral H.P., single phase units (115/230v.) are furnished with magnetic starters mounted and wired on the unit. Single phase fractional H.P. motors have built-in overload protection and do not require magnetic starters.

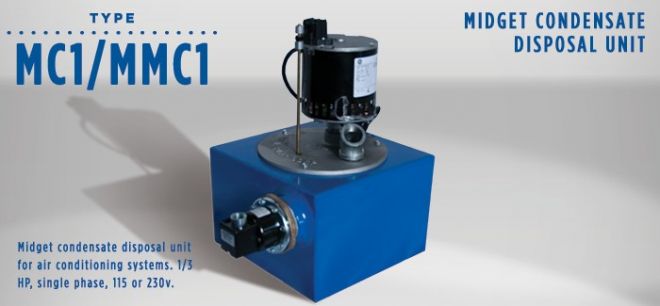

MC1/MMC1 Condensate Units

TANK: Heavy fabricated steel-5 gallon capacity.

PUMP: Standard-fitted construction with stainless steel shaft, bronze bearing and aluminum impeller. Pump has a capacity of 5 G.P.M. at a maximum pumping head of 20 Feet.

MOTOR: 1/3 H.P., 1750 R.P.M., single phase, 60 cycle, 115 or 230 volts, with built-in overload protective device. 115 volt motor is supplied with covered extension cord and plug. 230 volt motor is supplied with conduit box for electrical connection.

FLOAT SWITCH: Built into motor and fully protected from damage. Operated by float ball, rod, and adjustable stops.

OPTIONAL HIGH WATER CUT-OUT AND ALARM SWITCH: (MMC-1 UNIT) Standard MC-1 unit can be modified by the addition of an extra integral float switch with one set of normally open and one set of normally closed contacts. This modification is called the MMC-1 unit. On the MMC-1 unit the float switch is actuated if water in the tank rises to a dangerous level. Switch will automatically shut down the air conditioning unit and simultaneously activate an audible or visual alarm, thus preventing overflow from the tank.

MCH Condensate Units

TANK: Heavy welded steel. No foundation bolts are required.

PUMP: Bronze-fitted centrifugal pump design assures long operating life without loss of efficiency. Stainless steel shaft, bronze guide bearing, protected by mechanical shaft seal. Single piece cast iron construction insures vibration less operation.

MOTOR: 3450 RPM , single phase, 60 cycle, 115V. or 230V., with built in overload protection, in drip proof enclosure. 115V. motors have integral extension cord and grounded plug. 230V. motors have terminal for power wiring.

FLOAT SWITCH: Fully enclosed automatic on-off float switch mounted on motor operated by stainless steel float and rod.

VCU Condensate

RECEIVING TANK: 3/16” thick copper bearing steel fitted with gauge glass, stainless steel dial type thermometer, stainless steel pressure and vacuum gauges, and isolation valves for pumps.

PUMPS: bronze fitted centrifugal, flange mounted to the receiver with 250 degree rated mechanical shaft seals, the seal chamber has a relief line back into the receiver to prevent air pockets or collection of abrasives near the mechanical seal. Motor and rotating assemblies are removable without disturbing discharge or return piping.

MOTOR: open drip proof close coupled to pump(s).

CONTROLS: nema 12 contrl simplex or duplex units is across the line magnetic starter(s) thermal overload(s), hand selector switch(s) pump lite(s) and momentary test for each motor, mechanical float switch for condensate switch for air pumps, water condensate float temperature switch.

VRC Condensate Units

RECEIVER: Single piece cast iron. Rated for a maximum internal pressure of 5 psi. Designed for venting to atmosphere.

PUMP: Bronze-fitted centrifugal design, flanged to the receiver, with leakless mechanical seal. The seal chamber has a relief line back into the receiver to prevent air pockets or collection of abrasives near the mechanical seal. The motor and rotating assembly are removable without disturbing the return or discharge piping. Maximum water temperature at the pump suction is 210degrees F.

MOTOR: Drip-proof ball bearing design, operating at 3450 R.P.M. or 1750 R.P.M. Single phase motors are rated 115/230V. Three phase motors are rated 208-230/460V.

FLOAT SWITCH: Single units have a float switch (mounted and wired on the unit) to automatically operate the pump. Duplex units have an alternating float switch (mounted and wired on the unit) to automatically alternate the operating cycles of the pumps and provide simultaneous operation when required.

BFV Boiler Feed Units

RECEIVING TANK: Heavy steel construction, mounted on steel saddles fitted with thermometer and gauge glass.

MAKEUP WATER VALVE: All-bronze float actuated valve, flange mounted in tank head, permits entry of makeup water, when required, to replace system losses. Complete with strainer on makeup water connection.

PUMP(S): Close-coupled, bronze-fitted, centrifugal design, with leakless mechanical shaft seal.

MOTOR(S): Drip-proof ball bearing type close-coupled to pump(s). Single phase motors in fractional H.P. frame sizes have built-in thermal overload protection. Single phase motors in integral H.P. frame sizes, and all 3 phase motors, are furnished with magnetic starters in NEMA 1 general purpose wall-mounting enclosures. Units are available with 1750 R.P.M. or 3450 R.P.M. motors (see Engineering Selection Table).

UNITS: Unit is factory assembled. Simplex unit has one receiving tank, one makeup valve and one pump and motor. Duplex unit has one receiving tank, one makeup valve, and two pumps and motors. Triplex unit has one receiving tank, one makeup valve and three pumps and motors. Quadruplex unit has one receiving tank, one makeup valve and four pumps and motors.

VB 1-1/2D Column Pump

MOTOR:Standard NEMA frame sizes. Ball bearings are factory sealed and do not require field lubrication. Drip-proof motors are standard. Totally enclosed and explosion-proof motors also available. Single phase (115/230V.) motors have built-in thermal overload protection. Three phase (208-230/460v.) motors should be provided with magnetic starters.

FLOAT SWITCH: Double break type in steel enclosure, actuated by copper float with brass rod and stops.

COUPLING: Single-piece type with adjustable set screws.

HANGAR PIPE: Rigid steel pipe support insures accurate alignment.

SUSPENSION PLATE: 14" Diameter steel suspension plate is standard on Fig. 3 units. Split type cast iron adjusting collar is available for field adjustment of length of pump extension below suspension plate.

DISCHARGE PIPE: Included on Fig. 3 units only. Discharge size is 1.5"

VF2 Column Pump

MOTORS: Nationally recognized manufacture in standard NEMA frame sizes and mounted on rigid single piece cast iron pedestals, rabbetted to assure perfect alignment on pump and motor shaft. Ball bearings are sealed against dirt and moisture and do not require field lubrication. Motors on standard units are drip-proof. Totally enclosed and explosion proof motors also available. Single phase (115/230v.) motors have built-in thermal overload protection in fractional frame sizes. Single phase motors in integral frame sizes and 3 phase (208- 230/460V) motors should be provided with magnetic starters.

FLOAT SWITCH: Double break switch in steel enclosure, actuated by copper float, with brass rod and stops.

FLEXIBLE COUPLING: Precision machined with one-piece load cushion. No wear on metal jaws; load is absorbed by cushion compression.

SUSPENSION PLATE: Fourteen inch diameter cast iron suspension plate is standard. Twenty inch diameter steel suspension plates also available.

VSA SEWAGE COLUMN PUMP

MOTOR: Nationally known manufacturer. Single phase motors in fractional horsepower frame sizes have built-in overload protection. Other motors should be protected by magnetic starters.

FLEXIBLE COUPLING: Machined and balanced.

THRUST BEARING: Ball bearing mounted above suspension plate in dust-proof and moisture-proof housing.

ADJUSTING NUTS: Two bronze lock nuts for accurate vertical adjustment of impeller clearance.

SUSPENSION PLATE: Cast iron plate has integral strengthening ribs.

DISCHARGE PIPE: Steel, locked to suspension plate, held in bottom elbow by mating flange, forming bottom expansion joint.

TOP DISCHARGE ELBOW: Cast iron 45 degree elbow with integral 125# ASA standard discharge flange and top expansion joint ring.

Federal Pump Series VSP Variable Speed booster systems combine over 87 years of Federal Pump product reliability with practical energy efficient designed system solutions where water pressure challenges exist. Available in simplex, duplex and triplex arrangements, Series VSP variable speed pressure regulated systems provides automatic operation and ease in maintenance.

Capacities to 800GPM

Pressure Boost to 100PSI*

Sizes 2.5” to 6” Manifolds

HP to 40 each pump

Available in single and three phase power

*Higher pressure available-Consult local sales office

- Condensate Tanks

- Boiler Feed

- Column Sump Pumps

- Booster Systems