In 1689, the physicist Denis Papin invented the centrifugal pump. Today, this kind of pump is the most commonly used around the world. The centrifugal pump is built on a simple principle: Liquid is led to the impeller hub and is flung towards the periphery of the impeller by means of centrifugal force. The construction is fairly inexpensive, robust and simple, and its high speed makes it possible to connect the pump directly to an asynchronous motor. The centrifugal pump provides a steady liquid flow, and it can easily be throttled without causing any damage to the pump.

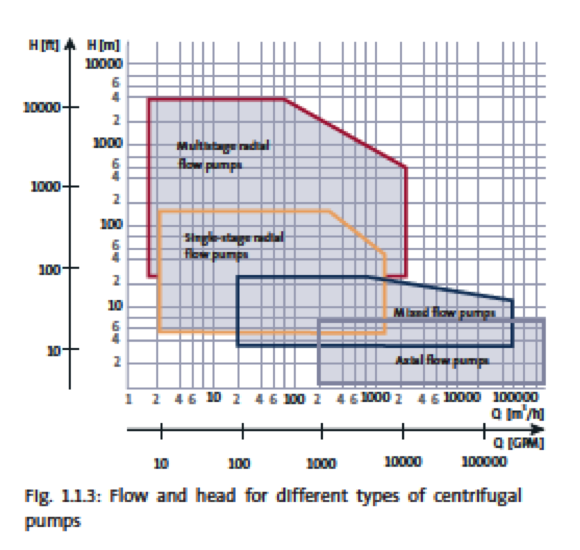

See figure 1.1.1 for liquid flow through the pump.

Fig. 1.1.1: The liquids flow through the pumpThe inlet of the pump leads the liquid to the center of the rotating impeller from where it is flung towards the periphery. This construction provides high efficiency and is suitable for handling pure liquids. Pumps which have to handle impure liquids, such as waste-water pumps, are fitted with an impeller that pre-vents objects from getting lodged inside the pump, see section 1.2.5.

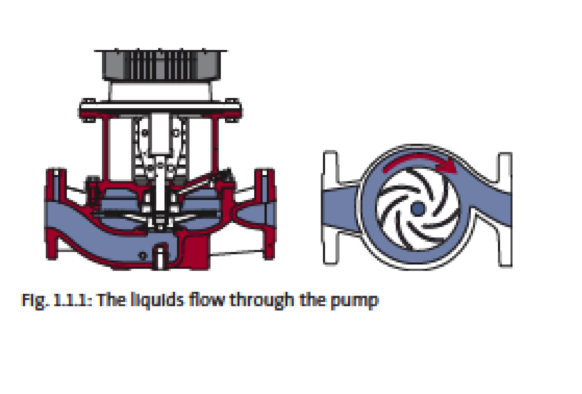

If a pressure difference occurs in the system while the centrifugal pump is not running, liquid can still pass through due to its open design. As you can tell from figure 1.1.2, the centrifugal pump can be categorized in different groups: Radial flow pumps, mixed flow pumps and axial flow pumps. Radial flow pumps and mixed flow pumps are the most common. These types of pumps are discussed on the following pages with a brief presentation of a positive displacement pump in section 1.2.8.

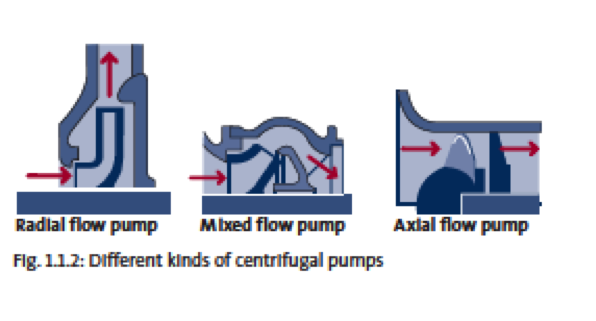

The different demands on the centrifugal pump’s performance, especially with regard to head, flow, and installation, together with the demands for eco-nomical operation, are only a few of the reasons why so many types of pumps exist. Figure 1.1.3 shows the different pump types with regard to flow and head....Learn more by downloading the GRUNDFOS PUMP HANDBOOK